Colloid Mill Machine Manufacturers in Maharashtra

Colloid Mill Machine Manufacturers in Maharashtra

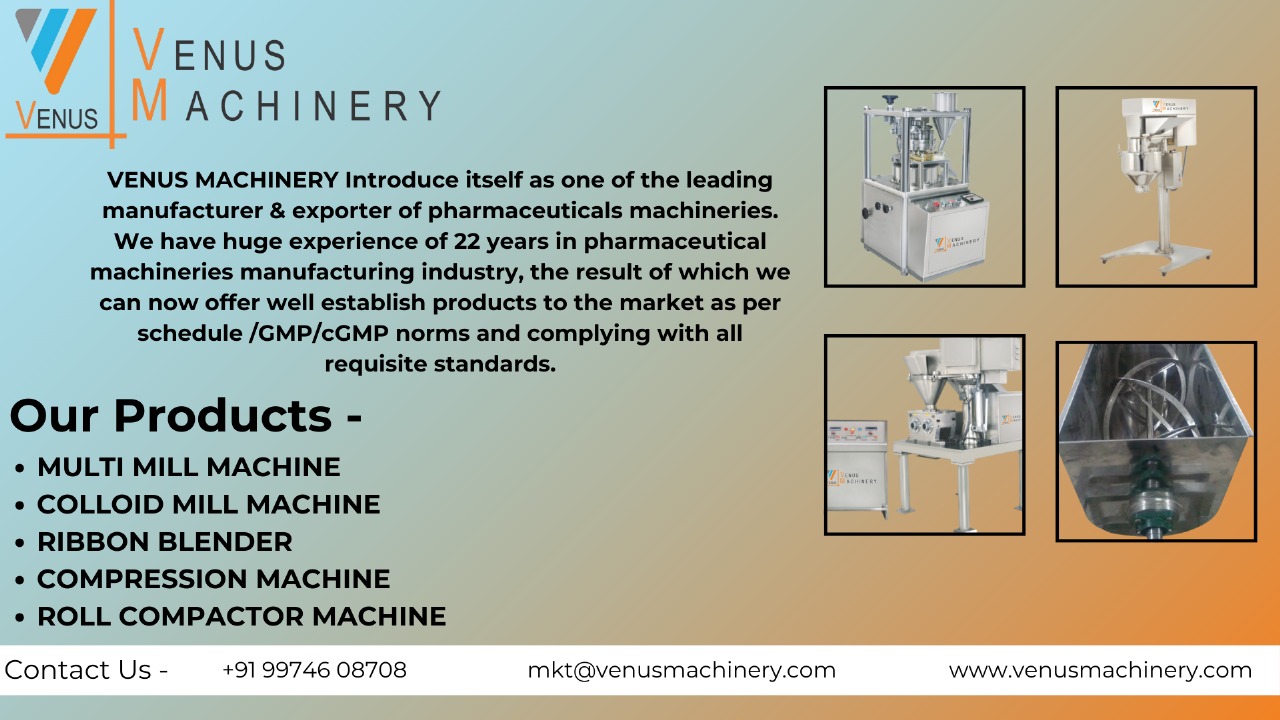

Maharashtra is a hub for high-quality colloid mill machinemanufacturers, offering precision-engineered solutions designed

for consistent particle size reduction and efficient emulsification,

homogenization, mixing, and dispersion. These machines are extensively used in

pharmaceutical, food, chemical, cosmetic, and allied industries.

FAQs About Colloid Mill Machines

- What is a colloid mill

machine?

A colloid mill is a machine used to reduce particle size and achieve fine emulsions and suspensions through high shear forces between a rotor and stator. - Which industries commonly

use colloid mills?

Pharmaceutical, food and beverage, chemical, cosmetic, and textile industries utilize colloid mills for various applications. - What materials can be

processed in a colloid mill?

Colloid mills can process liquids to highly viscous products, including creams, ointments, sauces, and adhesives. - What is the typical particle

size reduction achieved?

Colloid mills can reduce particle sizes to as low as 5 to 10 microns, depending on the material and machine specifications. - Are colloid mills suitable

for heat-sensitive products?

Yes, many colloid mills come with water jacketed models to handle heat-sensitive materials effectively. - Can colloid mills handle

continuous operations?

Yes, colloid mills can be used for both batch and continuous processing, depending on the design. - How is the grinding gap

adjusted?

Most colloid mills feature an adjustable gap between the rotor and stator, allowing control over the fineness of the output. - What maintenance is required

for colloid mills?

Regular cleaning and inspection of wear parts like rotors and stators are essential. Many models are designed for easy disassembly and cleaning. - Are there different models

available?

Yes, manufacturers offer various models, including lab-scale, pilot-scale, and production-scale colloid mills, with different capacities and features. - Do colloid mills comply with

GMP standards?

Reputable manufacturers design their colloid mills to meet Good Manufacturing Practice (GMP) standards, ensuring quality and safety.

Key Benefits of Colloid Mill Machines

- High Efficiency: Achieves fine particle size

reduction and uniform mixing.? Versatility: Suitable for a wide

range of products and viscosities.?

- Compact Design: Occupies minimal space,

ideal for facilities with space constraints.?

- Easy Maintenance: Designed for quick disassembly and cleaning.?

- Scalability: Available in various sizes

to suit different production scales.?

Common

Uses

- Pharmaceuticals: Preparation of ointments,

creams, suspensions, and emulsions.?

- Food Industry: Production of sauces,

dressings, and other emulsified products.?

- Cosmetics: Manufacturing of lotions, creams, and gels.?

- Chemicals: Processing of paints, inks,

and adhesives.

- Textiles: Preparation of dye

solutions and other chemical mixtures.?

Industrial Applications

- Homogenization: Ensures uniform distribution of components in a mixture.?

- Emulsification: Combines immiscible liquids

into stable emulsions.?

- Particle Size Reduction: Breaks down particles to

desired sizes for specific applications.?

- Mixing: Combines multiple

ingredients into a consistent product.?

- Dispersing: Evenly distributes solid

particles within a liquid medium.

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Supplier in Gujarat

- High‑Efficiency Fluid Bed Dryer Gujarat

- High-Efficiency Fluid Bed Dryer Gujarat

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) � Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender � Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine