Industrial Roll Compactor Machine Manufacturer Solutions

Industrial Roll Compactor Machine Manufacturer Solutions

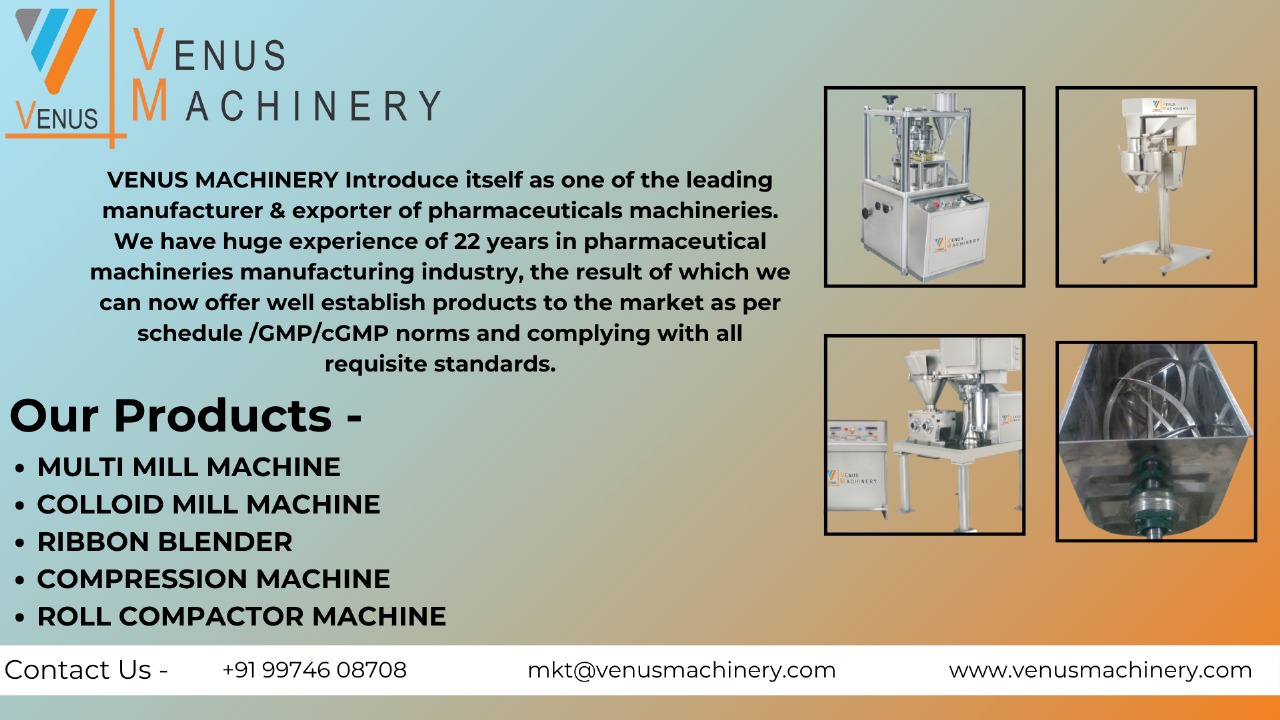

As a

leading industrial roll compactor machine manufacturer in India, we deliver

advanced and efficient dry granulation systems tailored for pharmaceutical,

chemical, food, and mineral industries. Our machines ensure uniform particle

size, reduced dust generation, and optimized bulk density, helping industries

enhance productivity with precision.

Frequently Asked Questions (FAQs):

- What is a roll compactor

machine?

A roll compactor is used for dry granulation, where powders are compacted between rollers and then milled into granules. - Which industries use roll

compactors?

Primarily used in pharmaceutical, chemical, nutraceutical, and food industries. - How does it differ from a

tablet press?

A roll compactor creates granules, whereas a tablet press compresses powder into solid tablets. - Is this machine suitable for

moisture-sensitive materials?

Yes, it's ideal for materials that can't be wet-granulated. - What are the main components

of a roll compactor?

Feed system, compaction rolls, flake crusher, and granulator. - Can I get a customized

model?

Yes, we offer customization based on throughput and product type. - What is the maintenance

frequency?

Minimal maintenance is required; regular cleaning and lubrication are sufficient. - Are your machines GMP

compliant?

Absolutely, all machines follow GMP standards for hygienic processing. - Do you offer after-sales

support?

Yes, we provide complete installation, training, and support services. - What is the output capacity

of your roll compactors?

Ranges from 5 kg/hour to several hundred kg/hour depending on model.

Applications:

- Pharmaceutical granulation

- Nutraceutical powder

processing

- Chemical material compaction

- Food additive granulation

- Dry fertilizer granules

production

- Pigments and colorants

densification

Key Features:

- Heavy-duty rollers with

pressure adjustment

- Variable speed control

- High output capacity with

minimal downtime

- Integrated granulator and

flake crusher

- Stainless steel construction

(GMP grade)

- PLC-based automation (optional)

- Easy cleaning and

maintenance

- Dust-tight design for

hygiene

Uses:

- To compact fine powders into

granules

- Enhancing flowability of raw materials

- Increasing bulk density

- Reducing dust and material

loss

- Preparing materials for

tablet pressing

Benefits:

- Cost-effective dry

granulation solution

- No need for binding agents

or solvents

- Environmentally friendly –

low dust emission

- Easy scalability for

production lines

- Uniform granule size

improves downstream processing

- Enhances product handling and packaging efficiency

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Supplier in Gujarat

- High‑Efficiency Fluid Bed Dryer Gujarat

- High-Efficiency Fluid Bed Dryer Gujarat

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) – Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender – Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine