Roll Compactor Machine

Roll Compactor Machine

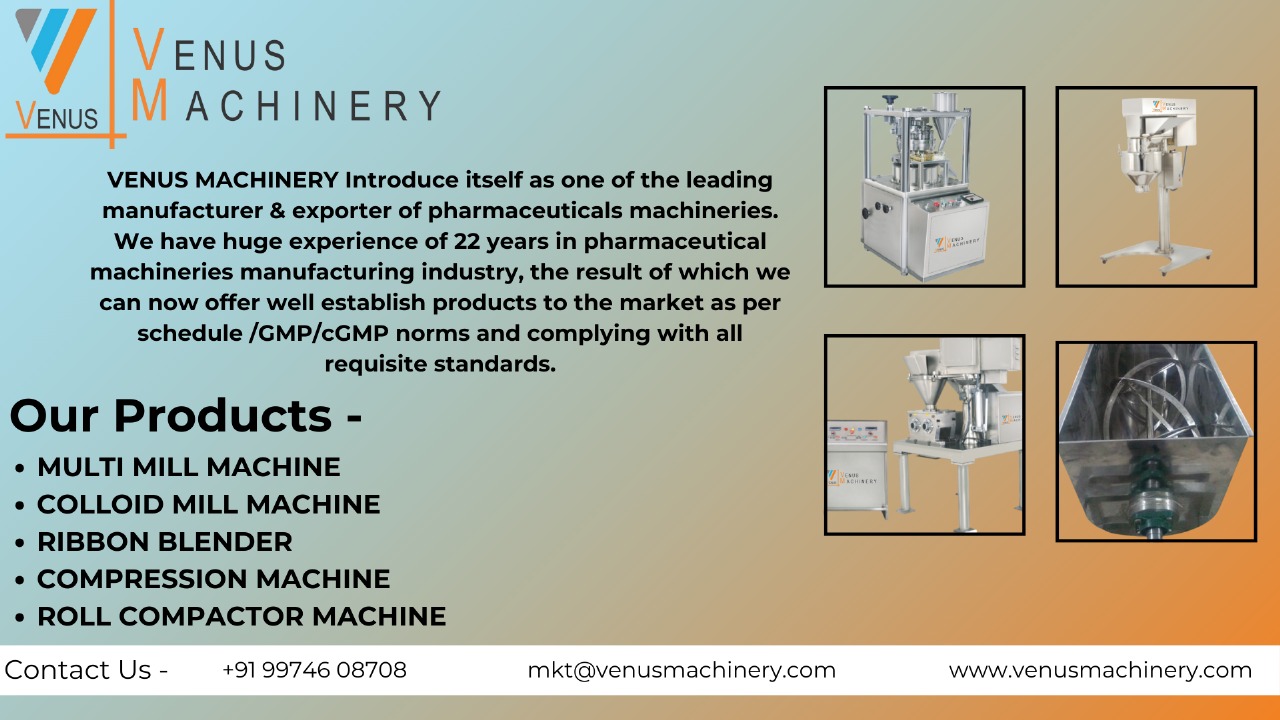

A RollCompactor Machine is a type of equipment used in the pharmaceutical,

chemical, and food industries for dry granulation processes. It works by

compacting powdered material into sheets or ribbons using two counter-rotating

rolls, applying both pressure and shear force to compress the powder into dense

sheets. These sheets are then broken into granules, which can be used for

further processing such as tableting or encapsulation. Roll compactors are

widely used for materials that are difficult to process via wet granulation and

are ideal for creating uniform granules with controlled size distribution. This

machine helps in improving product quality, increasing production capacity, and

optimizing material usage. Roll compactors are valued for their efficiency in

handling high-volume production while minimizing material waste.

10 FAQs for Roll Compactor Machine

- What is a roll compactor

machine?

- A roll compactor machine is a piece of equipment used for dry

granulation, where powders are compacted into dense sheets or ribbons

using two rolls. These ribbons are then broken down into granules, which

are used in tablet and capsule manufacturing.

- How does a roll compactor

machine work?

- The machine works by

feeding powder into the gap between two rotating rolls. As the rolls

rotate, pressure is applied to the powder, compacting it into sheets.

These sheets are then broken into granules of desired size.

- What materials can be

processed with a roll compactor machine?

- Roll compactors are suitable for

processing powders and granules in industries like pharmaceuticals,

chemicals, food, and cosmetics. They can handle materials like active

pharmaceutical ingredients (APIs), excipients, spices, and other powdered

substances.

- What is the advantage of

using a roll compactor machine?

- The primary advantage is

that roll compactors facilitate dry granulation, which eliminates the

need for binders and solvents, reducing material costs and processing

time. They also provide uniformity in granule size, improving product

consistency.

- What are the different types

of roll compactors?

- There are primarily two

types of roll compactors:

- Single-roll compactors: Used for low-volume

production.

- Double-roll compactors: Offer higher capacity

and are suitable for large-scale operations.

- How is the granule size

controlled in a roll compactor machine?

- Granule size is controlled

by adjusting the roll gap, roll speed, and pressure applied to the

powder. The size of the granules can be further refined by controlling

the milling process after compaction.

- Can a roll compactor machine

be used for high-volume production?

- Yes, roll compactors are

ideal for high-volume production because they can process large

quantities of material in a continuous manner, making them suitable for

industrial-scale manufacturing.

- How often should maintenance

be performed on a roll compactor machine?

- Regular maintenance is

crucial for keeping the machine in optimal working condition. Maintenance

tasks typically include checking the rolls for wear, cleaning the system,

lubricating components, and inspecting the electrical and mechanical

parts for damage. Scheduled maintenance every 3 to 6 months is

recommended, depending on usage.

- Is a roll compactor machine

easy to operate?

- Roll compactors are

generally user-friendly and come with digital controls for easy setup and

operation. However, operators must be trained on how to adjust the

machine for different materials and granulation requirements.

- What are the benefits of dry

granulation using a roll compactor machine?

- Dry granulation helps

reduce the use of solvents and binders, which can be costly and introduce

contamination. It also leads to better uniformity and consistency in

granules, increased production rates, and more efficient processing of

moisture-sensitive materials.

Applications of Roll Compactor Machine

- Pharmaceutical Industry:

- Roll compactors are widely used in the

pharmaceutical industry to create granules for tablets and capsules. The

dry granulation process is particularly useful for heat-sensitive or

moisture-sensitive drugs, as it eliminates the need for water or

solvents.

- Chemical Industry:

- In the chemical industry,

roll compactors are used to granulate powdered chemicals, fertilizers,

and pigments. These machines help to improve the flow properties and

density of chemicals, making them easier to handle and package.

- Food Industry:

- Roll compactors are used

for producing granular materials in the food industry, such as spices,

flavorings, seasonings, and instant coffee granules. The machines help

ensure uniformity and consistency in the size of granules, which improves

product quality.

- Cosmetics Industry:

- Roll compactors are used in

the cosmetics industry to produce granules for powdered formulations like

face powders, blushes, or other pressed cosmetics. They also help in

creating compact powders with uniform properties.

- Nutraceuticals:

- Nutraceuticals such as

vitamins, dietary supplements, and herbal granules are produced using

roll compactors. These machines help in granulating difficult-to-process

ingredients and improving the uniformity of active ingredients.

- Agriculture:

- Roll compactors are employed in

agriculture to process fertilizers and pesticide granules. The machine

improves the consistency and flowability of fertilizers, ensuring

accurate dosage and application.

- Recycling and Waste

Management:

- Roll compactors can be used

to compact recyclable materials, reducing their volume and making them

easier to handle, store, and transport. This process also helps improve

the efficiency of waste management operations.

- Tobacco Industry:

- In the tobacco industry,

roll compactors are used to process tobacco powders into consistent

granules. These granules are then used in cigarette manufacturing,

ensuring uniformity in the final product.

- Paint and Coatings Industry:

- Roll compactors are used in

the paint and coatings industry to produce granular pigments and

additives. These machines help achieve a consistent particle size for the

effective mixing and application of paints and coatings.

- Refractories Industry:

- The roll compactor machine

is used in the refractories industry to produce granular materials used

in the production of heat-resistant bricks and materials. This ensures

uniformity and quality of the refractory products.

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) – Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender – Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine