Ribbon Blender

Ribbon Blender

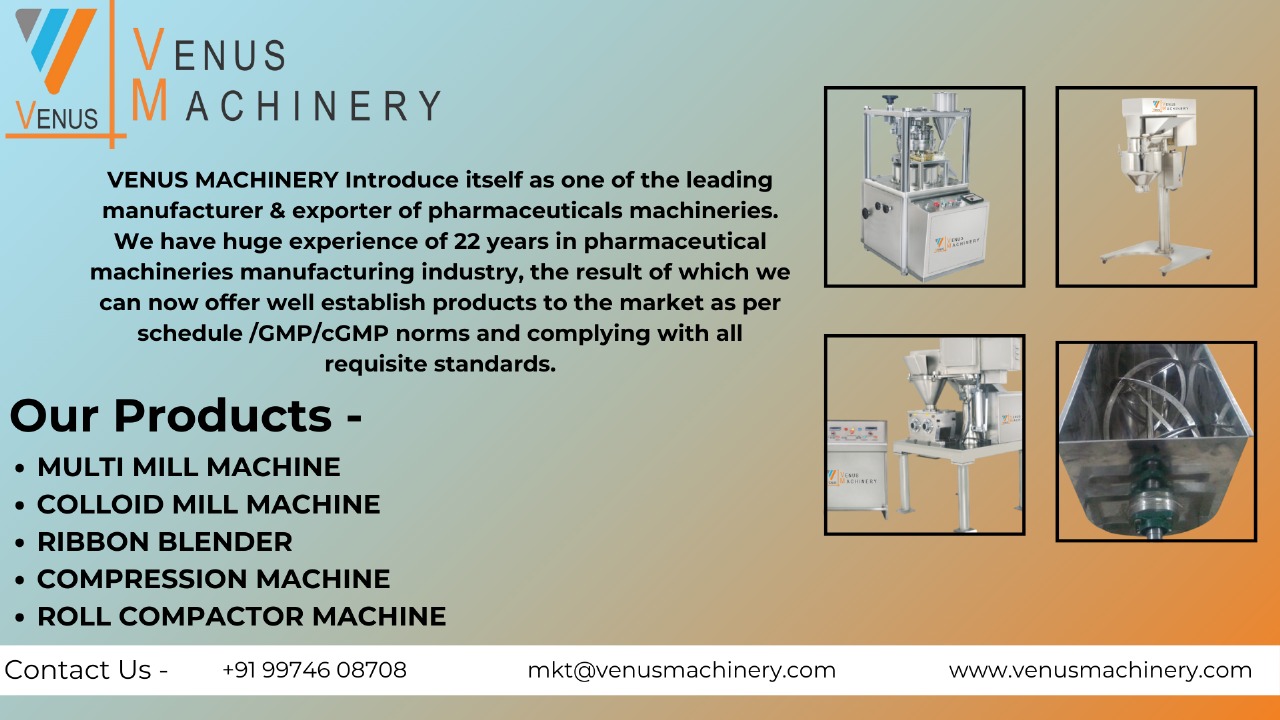

A RibbonBlender is a highly efficient and versatile industrial mixing machine used

to uniformly blend dry powders, granules, and even viscous pastes. It features

a U-shaped horizontal trough with a specially designed double-helical ribbon

agitator that ensures consistent and homogenous mixing. Widely used across

food, pharmaceutical, chemical, cosmetic, and plastic industries, the Ribbon

Blender is known for its low maintenance, high performance, and customizable

design.

FAQs – Ribbon Blender

- What is a ribbon blender

used for?

It is used for mixing dry powders, granules, or slightly wet materials in various industries. - How does a ribbon blender

work?

It uses a double-helical ribbon agitator that moves materials in opposite directions to achieve thorough blending. - Is a ribbon blender suitable

for liquid mixing?

It’s ideal for dry or slightly moist mixing; not suitable for high-volume liquid mixing. - Can ribbon blenders be

customized in size?

Yes, they are available in various capacities from 50 liters to several thousand liters. - What materials can be

processed in a ribbon blender?

Powders, spices, pharmaceuticals, cosmetic ingredients, detergent, plastic granules, and more. - Is the cleaning process easy?

Yes, most ribbon blenders have easy-access doors and smooth internal surfaces for quick cleaning. - What are the standard

materials used in construction?

Usually made from SS304, SS316 for food/pharma applications, or mild steel for industrial use. - Can it handle abrasive or

corrosive materials?

With proper material selection and coating, yes. - Is it energy-efficient?

Yes, it delivers high mixing performance with low power consumption. - Does it allow heating or

cooling during mixing?

Yes, jacketed ribbon blenders can be used for heating/cooling operations.

Applications

- Food Processing (spices, flours, seasoning blends)

- Pharmaceutical powders &

granules

- Cosmetic powders and creams

- Chemical powder blending

- Detergent mixing

- Plastic and polymer compound

mixing

- Animal feed preparation

- Paint and pigment industries

- Ceramic and mineral

industries

- Nutraceuticals and herbal

powder blends

Key Features

- Horizontal U-shaped trough

with robust construction

- Double-helical ribbon

agitator for uniform mixing

- Mild Steel or Stainless

Steel construction

- Capacities ranging from 50L

to 10,000L

- Option for jacketed design

for heating/cooling

- Discharge valve (butterfly,

slide gate, or ball valve)

- Easy cleaning with access

doors

- Efficient mixing time (5-15 minutes)

- Low energy consumption

- Customizable for batch or

continuous operations

Uses

- Homogeneous mixing of dry

powders

- Uniform mixing of granular

substances

- Incorporation of small

quantities of liquids in powders

- Coating of powders with

additives

- Pre-mix for extrusion or

molding operations

- Mixing of herbal and

medicinal powders

- Color blending in plastic or

pigment industry

- Additive mixing in rubber or polymer processing

Benefits

- Uniform & Consistent

Mixing:

Ensures product quality through homogenous blending.

- Versatile Application: Suitable for a wide range

of industries and materials.

- Low Maintenance: Simple design with minimal

wear parts.

- Customizable Design: Tailored to specific mixing

needs and capacities.

- Fast Mixing Time: Efficient mixing cycle

reduces batch time.

- Durable Construction: Built for long-term

industrial use.

- Scalable Options: Available in various sizes

for small or large batch production.

- Energy Efficient: Delivers high output with

low power usage.

- Easy to Clean: Ideal for industries with

high hygiene standards.

- Cost-Effective Operation: Low operational cost

compared to other mixing technologies.

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) – Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender – Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine