Double Cone Blender Manufacturer Near Me

Double Cone Blender Manufacturer Near Me

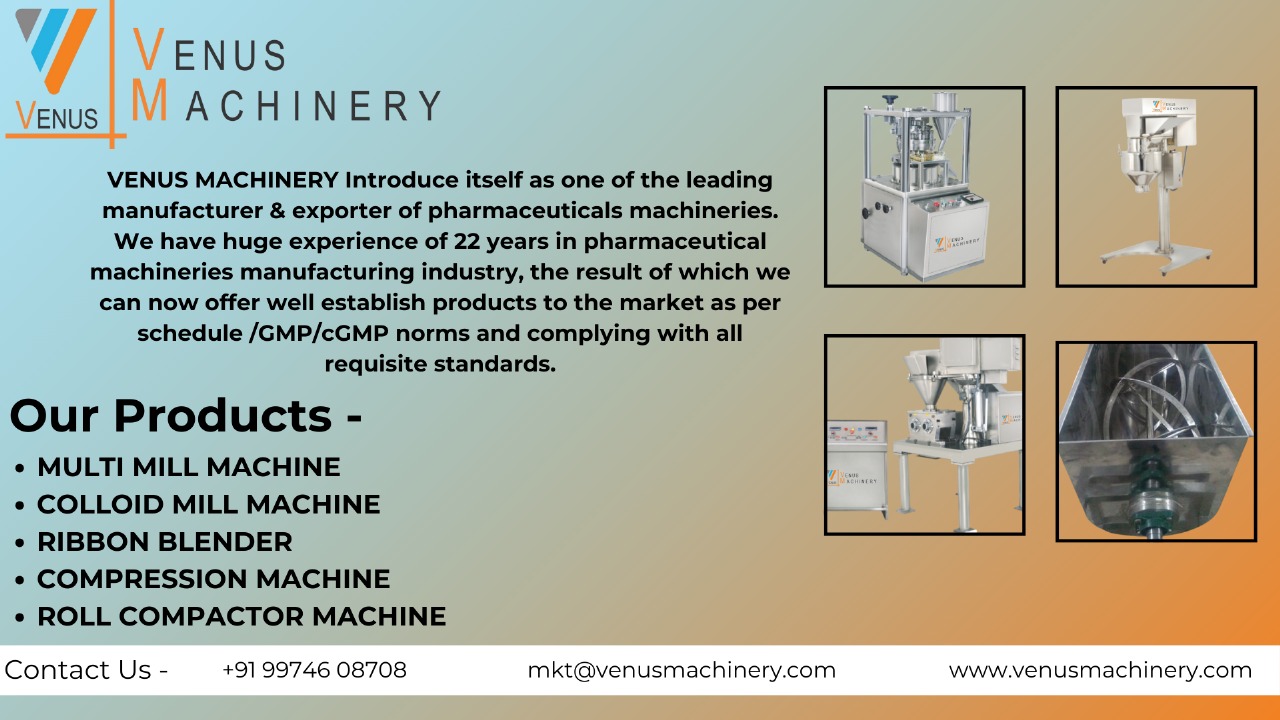

Looking

for a reliable Double Cone Blender manufacturer near you? We specialize

in producing high-performance, GMP-compliant Double Cone Blenders designed for

uniform mixing of dry powders and granules in pharmaceuticals, food, chemicals,

and cosmetic industries. Our blenders offer gentle blending action, easy cleaning,

and customizable capacities — all built with precision engineering and robust

stainless-steel construction.

FAQs

- What is a Double Cone

Blender used for?

It’s used to mix dry powders and granules uniformly in various industries. - What materials are used to

manufacture the blender?

Typically stainless steel (SS304/SS316) for hygiene and durability. - Is it suitable for

food-grade products?

Yes, it is designed for food, pharmaceutical, and cosmetic-grade processing. - How long does mixing take?

Average blending time ranges between 10–30 minutes depending on the material. - Can it handle abrasive

materials?

Yes, with custom lining or material specifications. - Do you offer custom

capacities?

Yes, from 5 liters to over 5000 liters as per user requirements. - Is the machine easy to

clean?

Yes, the design allows easy access and cleaning, especially with detachable covers. - What kind of maintenance is

required?

Periodic checks on bearings, gaskets, and surface cleaning are sufficient. - Can it be automated or

integrated into a line?

Yes, with PLC systems and batch integration if required. - Do you provide installation

and after-sales service?

Absolutely — local support is available for maintenance, spares, and upgrades.

Applications

- Pharmaceutical Industry – Mixing active ingredients

and excipients

- Food Industry – Blending spices, flours,

and nutritional powders

- Chemical Industry – Powdered chemicals,

pigments, and catalysts

- Cosmetic Industry – Talc, face powders, and

cosmetic blends

- Nutraceuticals – Protein mixes, supplements,

herbal products

- Ceramics & Plastics – Granule and additive

blending

- Detergents – Uniform mixing of base powders

Key Features

- Double-conical design

ensures efficient, uniform mixing

- GMP-compliant construction using SS304/SS316

- Available in capacities

ranging from 5 to 5000 liters

- Dust-free charging and

discharging

system

- Optional intensifier bars

for cohesive materials

- Easy to clean and maintain

- Built-in safety features

and overload protection

- Variable speed drive options

- Manual or PLC-controlled

operation

- Mounted on robust frame with

smooth rotation

Uses

- Homogenizing pharmaceutical

powders

- Dry powder blending for food

production

- Pigment and chemical

mixtures

- Herbal and dietary supplement production

- Powder coating pre-mix

- Blending of powdered

detergents

- Pre-processing for tablet

and capsule manufacturing

Benefits

- Uniform & Homogeneous

Mixing

- Gentle Tumbling Action

Preserves Particle Integrity

- Customizable to Process

Needs & Volumes

- Hygienic & GMP-Grade

Design

- Easy Loading, Discharging

& Cleaning

- Minimal Power Consumption

- Safe & Operator-Friendly

Interface

- Long-Lasting Build Quality

- Compact Footprint for Space

Saving

- Available with Local Support

& Fast Delivery

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) – Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender – Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine