Roll Compactor Manufacturers in India

Roll Compactor Manufacturers in India

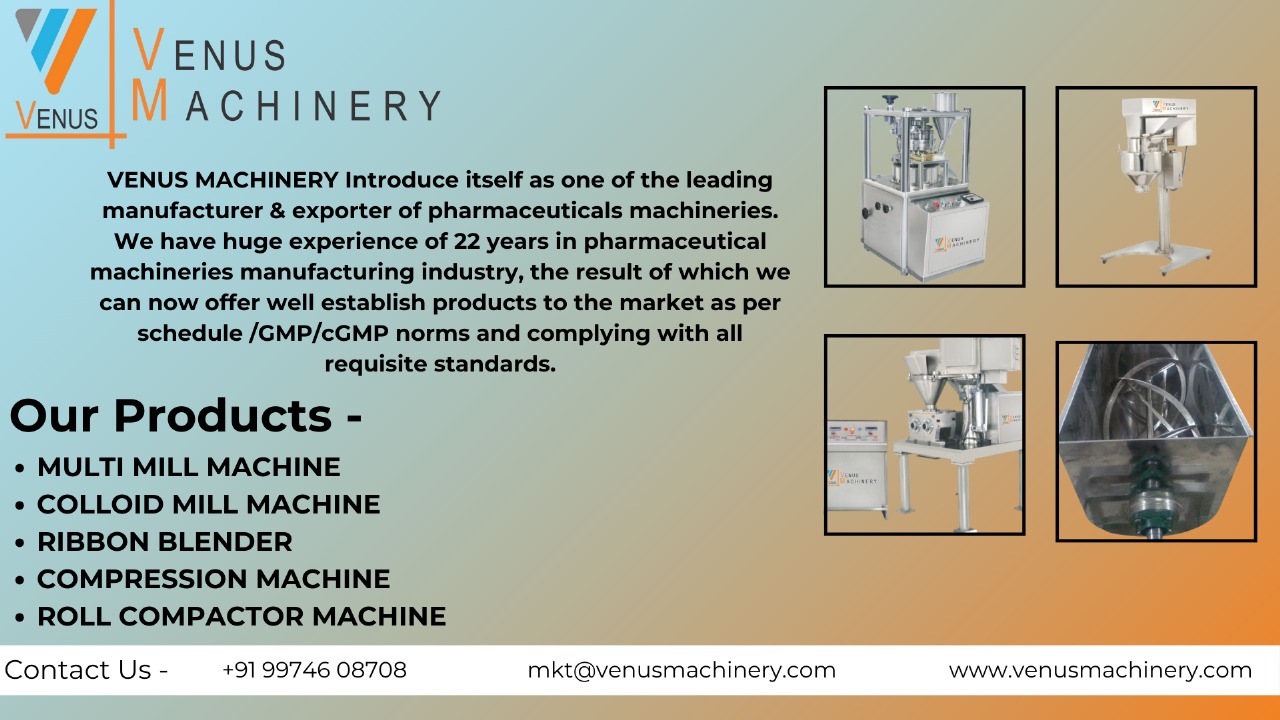

Roll

compactor manufacturers in India specialize in supplying advanced dry

granulation equipment used widely in the pharmaceutical, chemical, and foodindustries. These machines are designed to convert powdery materials into

uniform granules, improving flow properties and reducing dust. Indian

manufacturers are known for delivering durable, cost-effective, and

GMP-compliant roll compactors to meet both domestic and global demands.

FAQs

- What is a roll compactor?

A roll compactor is a dry granulation machine that compresses powder between two counter-rotating rolls into flakes or sheets, which are then milled into granules. - Where is a roll compactor

used?

It’s mainly used in the pharmaceutical, nutraceutical, chemical, and food industries for improving material handling. - What types of roll

compactors are available in India?

You can find laboratory models, pilot-scale units, and production-grade compactors, often with automatic control systems. - Are Indian roll compactors

GMP compliant?

Yes, most reputable Indian manufacturers provide GMP-compliant, CE-marked, and FDA-certified machines. - Can roll compactors handle

heat-sensitive materials?

Yes, as they do not involve heat, making them ideal for thermally sensitive powders. - What is the granule size

range?

Typically, granules range between 0.5 to 2 mm, but can be adjusted. - Do these machines require

high maintenance?

No, Indian roll compactors are designed for low maintenance with long-lasting components. - Is customization possible?

Yes, most Indian manufacturers offer customized designs based on material flow properties and industry needs. - Are Indian manufacturers

exporting these machines?

Absolutely! India is a major exporter of roll compactors to Asia, Europe, Africa, and the Americas. - How can I choose the right

manufacturer in India?

Look for ISO certifications, industry reputation, client testimonials, and post-sales support.

Applications

- Pharmaceutical Tablet

Manufacturing

- Nutraceutical Powder

Compaction

- Detergent Powder Densification

- Catalyst Preparation in

Chemicals

- Dry Granulation in Food

Processing

- Agrochemical Granule

Production

Key Features

- Stainless Steel

(SS316/SS304) construction

- Hydraulic roll pressure

system

- PLC/HMI-based control panel

- Variable roll speed

- Automatic granulation system

- Compact footprint for easy

installation

- Low noise & dust

emission

Uses

- Improve bulk density of

powders

- Enhance flow properties for

downstream processing

- Prepare material for

tableting or capsule filling

- Reduce dust and contamination risks

- Eliminate the need for wet

granulation

Benefits

- No need for binders or

drying steps

- Environmentally friendly – minimal energy and water

usage

- Consistent and reproducible

granule quality

- Reduced production time

- Cost-effective and scalable

for mass production

- User-friendly interface and

operation

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) – Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender – Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine