Ribbon Blender Manufacturer in Ahmedabad

Ribbon Blender Manufacturer in Ahmedabad

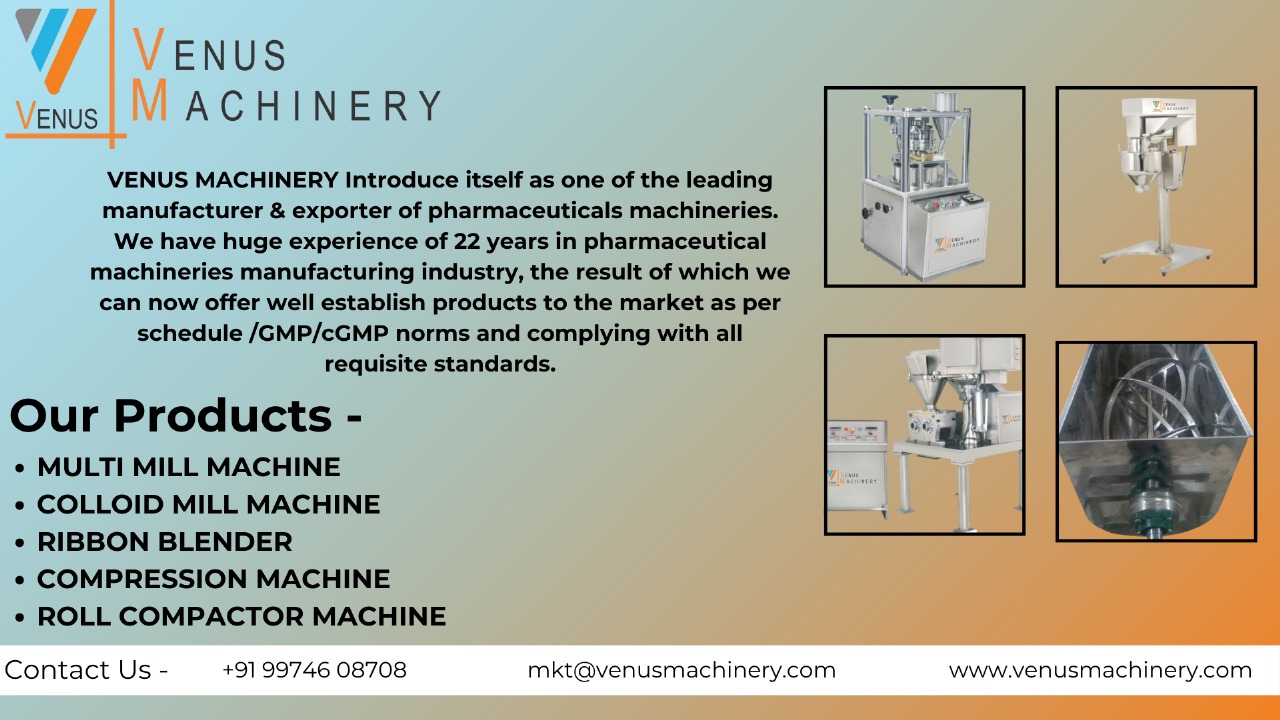

As a leadingRibbon Blender Manufacturer in Ahmedabad, we specialize in providing high-quality,

durable, and efficient mixing solutions for industries like pharmaceuticals,

food processing, chemicals, and cosmetics. Our Ribbon Blenders

are designed to handle dry powder mixing and granules with ease

and consistency, ensuring homogeneous blends every time.

FAQs: Ribbon Blender Manufacturer in Ahmedabad

- What is a Ribbon Blender?

A Ribbon Blender is a mixing machine that uses a dual ribbon design to blend dry powders and granules uniformly by rotating the ribbons around the chamber. - What industries use Ribbon

Blenders?

Ribbon Blenders are widely used in pharmaceuticals, food processing, chemicals, plastics, and cosmetics industries for dry powder and granular material mixing. - How does a Ribbon Blender

work?

The Ribbon Blender works by rotating two ribbons, one moving material towards the center and the other moving it outward, creating a continuous mixing action for uniform blending. - What are the advantages of a

Ribbon Blender?

Some key benefits include uniform mixing, energy efficiency, low maintenance, and the ability to handle both small and large volumes of material. - Can Ribbon Blenders handle

both dry and wet ingredients?

Yes, Ribbon Blenders are highly effective for dry ingredients but can also handle wet materials when used in combination with proper design adjustments. - What is the capacity of

Ribbon Blenders?

The capacity of a Ribbon Blender varies depending on the model, ranging from small-scale lab mixers to large industrial blenders capable of processing several tons of material per batch. - What materials are Ribbon

Blenders made of?

Ribbon Blenders are typically made from stainless steel (SS 304/316) or Mild Steel with options for food-grade finishes, depending on the industry requirements. - Are Ribbon Blenders

customizable?

Yes, Ribbon Blenders can be customized to meet specific material handling needs, such as heat-resistant blenders, adjustable ribbon speeds, or different mixing volumes. - Is the Ribbon Blender easy

to clean?

Yes, Ribbon Blenders are designed for easy cleaning and maintenance, with many models featuring removable parts and smooth surfaces to minimize material residue. - How does the Ribbon Blender

differ from other mixers?

Ribbon Blenders offer superior uniformity in mixing compared to other machines like V-blenders or paddle mixers, especially for fine powders and granules.

Applications of Ribbon Blender

- Pharmaceuticals: Mixing active ingredients

and excipients for tablet or capsule production.

- Food Processing: Mixing ingredients like

flour, sugar, salt, and spices for uniform texture.

- Chemicals: Blending powders, pigments,

additives, and other dry chemicals.

- Cosmetics: Mixing powders, pigments,

and oils for cosmetic formulations.

- Plastics: Compounding polymers and

additives to create uniform plastic materials.

- Agriculture: Mixing fertilizers,

pesticides, and herbicides for effective distribution.

- Detergents: Producing uniform detergent powders by blending various ingredients.

- Paints and Coatings: Mixing pigments and resins

for consistent paint formulations.

- Animal Feed: Mixing feed ingredients for

livestock to ensure consistency and proper nutrient distribution.

- Ceramics: Blending clay and other

materials for ceramics production.

Benefits

of Ribbon Blender

- Uniform Mixing: Ribbon Blenders provide a high

degree of uniformity in blending dry powders and granules.

- Energy Efficient: Ribbon Blenders consume

less energy compared to other mixing machines, making them cost-effective.

- Versatility: They can handle a wide

range of material sizes and compositions, from fine powders to larger

granules.

- Easy Operation: With user-friendly

controls, they are simple to operate and maintain.

- High Throughput: Capable of mixing large

volumes of material in a short time, suitable for high-demand

production lines.

- Low Maintenance: The durable design ensures

long-lasting performance with minimal maintenance.

- Customizable: Ribbon Blenders can be custom-built to meet specific requirements for different industries.

- Safe and Hygienic: Stainless steel options

ensure easy cleaning and hygienic operation, especially for

food and pharma industries.

- Compact Design: Ribbon Blenders are

designed to occupy less floor space, making them ideal for both small and

large production units.

- Cost-Effective: They offer a high return

on investment with durable parts and energy-saving operations.

Common Uses of Ribbon Blender

- Mixing powdered ingredients in pharmaceuticals,

cosmetics, and food products.

- Granular material mixing for products like fertilizers and pesticides.

- Blending dry chemicals and powders for industrial

applications.

- Homogenizing ingredients for detergents, paints,

coatings, and animal feeds.

- Pre-blending raw materials for extrusion

or compression processes.

- Homogenizing formulations for various industrial,

food, and cosmetic applications.

- Compounding and blending for polymers and plastics.

- Creating uniform mixes for powder-based products

such as milk powders, spices, and instant soups.

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Supplier in Gujarat

- High‑Efficiency Fluid Bed Dryer Gujarat

- High-Efficiency Fluid Bed Dryer Gujarat

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) � Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender � Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine