Roll Compactor Machine Manufacturer in Ahmedabad

Roll

Compactor Machine Manufacturer in Ahmedabad

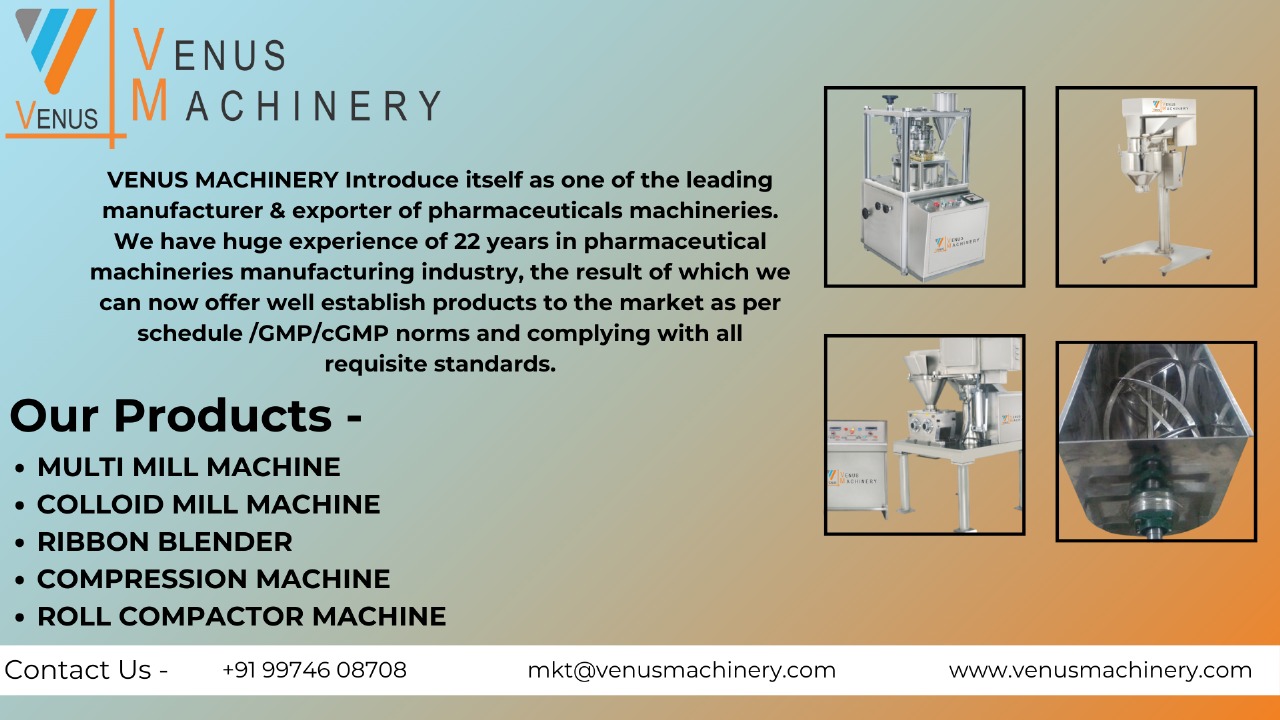

Looking

for the best Roll Compactor Machine Manufacturer in Ahmedabad? Leading

manufacturers in Ahmedabad design high-quality, efficient, and durable roll

compactor machines widely used in the pharmaceutical, chemical, and food

industries. These machines ensure dry granulation by compacting powder into

solid sheets or flakes without the need for liquid binders. Made with advanced

technology, precision engineering, and robust stainless steel materials, roll

compactors from Ahmedabad promise exceptional performance, low maintenance, and

maximum productivity.

FAQs:

- What is a roll compactor

machine?

? A roll compactor machine compresses powder into a dense sheet, which is then granulated into uniform particle sizes. - What industries use roll

compactors?

? Pharmaceuticals, chemicals, food processing, minerals, and cosmetics industries. - What materials can a roll

compactor handle?

? Powders that are sensitive to moisture or heat. - How does a roll compactor

work?

? It uses high-pressure rollers to compact dry powder into sheets and then granulates them. - Is it available in different

sizes?

? Yes, manufacturers offer machines in various capacities for lab-scale, pilot-scale, and production-scale needs. - Can I get a customized roll

compactor in Ahmedabad?

? Yes, many manufacturers provide customization based on your material and process requirements. - What is the typical price of

a roll compactor?

? It varies based on capacity, automation level, and features — typically ranging from ?5 lakh to ?30 lakh or more. - Do roll compactors meet GMP

standards?

? Yes, reputed manufacturers design machines according to GMP and cGMP standards. - Is installation and training

provided?

? Most top manufacturers offer installation, commissioning, and operational training. - What is the lifespan of a

roll compactor?

? With proper maintenance, it can last over 10–15 years.

Applications:

- Pharmaceutical tablet

manufacturing

- Dry granulation for

moisture-sensitive powders

- Food industry for granulated spices and ingredients

- Chemical industry for powder

compaction

- Metallurgical powder

processing

Key Features:

- Heavy-duty stainless steel

construction

- High-pressure hydraulic or

mechanical rollers

- User-friendly PLC control

system

- Adjustable compaction force

- Easy cleaning and

maintenance

- Safety interlocks

- Uniform granule size

distribution

- Water-cooled rollers (optional)

- Compact and robust design

- Energy-efficient motor drive

Uses:

- Compacting fine powder into

sheets

- Reducing dust generation

during processing

- Increasing bulk density of

powders

- Preparing materials for downstream granulation

- Dry granulation of

heat-sensitive or moisture-sensitive powders

Benefits:

- No Need for Binders: Perfect for

moisture-sensitive materials.

- Energy Efficient: Consumes less energy than

wet granulation processes.

- Improves Flow Properties: Enhances powder flowability

for easier handling.

- Customizable Outputs: Different granule sizes

achievable.

- Reduces Material Waste: Efficient compaction

reduces product loss.

- Meets Compliance Standards: Ideal for pharmaceutical

industry (GMP/cGMP).

- Low Maintenance: Durable parts with minimal

service needs.

- Scalable Solutions: Available for R&D,

pilot plant, and full production lines.

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Supplier in Gujarat

- High‑Efficiency Fluid Bed Dryer Gujarat

- High-Efficiency Fluid Bed Dryer Gujarat

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) – Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender – Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine