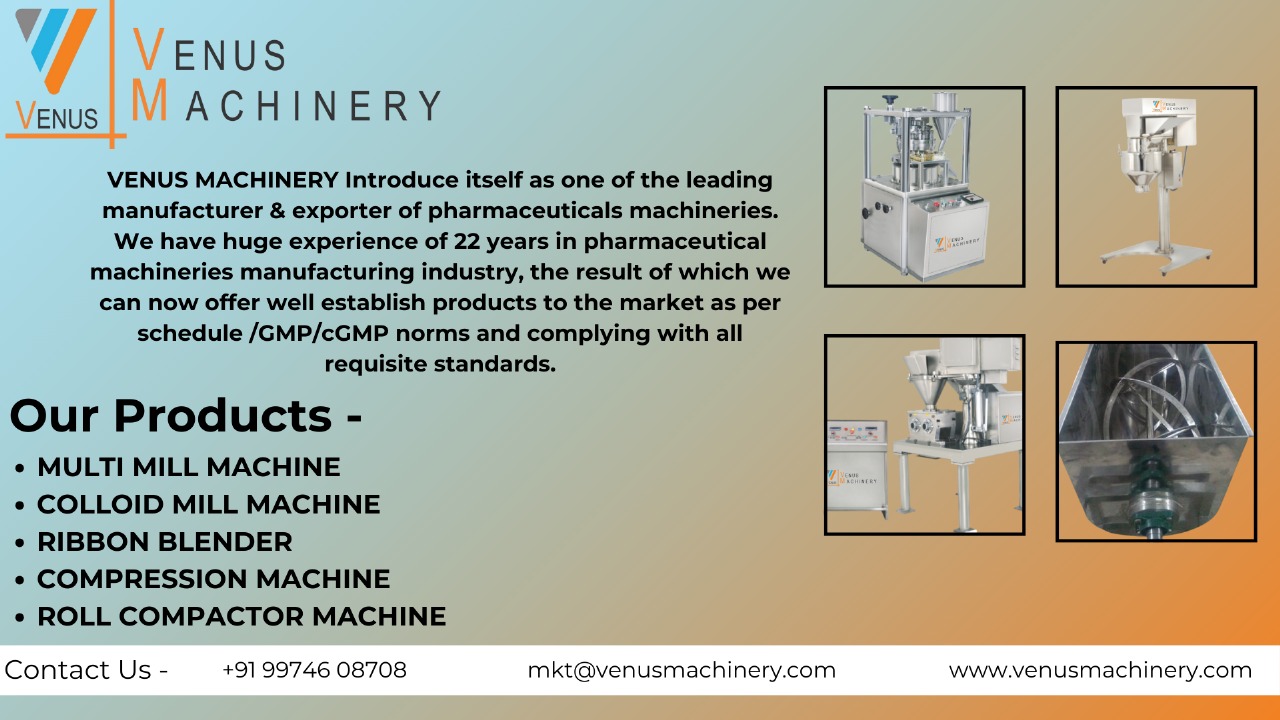

Industrial Multi Mill Machine

Industrial Multi Mill Machine

The IndustrialMulti Mill Machine is an essential piece of equipment in industries like

pharmaceuticals, chemicals, cosmetics, food processing, and more. It is a

versatile machine used for granulating, mixing, shredding, and blending

various materials into fine particles or powders. Its robust design allows it

to handle a wide range of materials, such as dry and wet granules, chemicals,

and even food ingredients. The multi-mill machine typically features a

high-speed rotor, multiple blades, and a screen assembly that

ensures the efficient and uniform size reduction of materials. The machine is

valued for its high capacity, durability, and ability to produce

consistent results.

FAQs for Industrial Multi Mill Machine

- What is an Industrial Multi

Mill Machine used for?

It is used for granulating, blending, mixing, and shredding various materials like powders, granules, chemicals, and food ingredients in industries such as pharmaceuticals, chemicals, and food processing. - How does a multi mill

machine work?

The machine uses a high-speed rotor with multiple blades to cut, shred, and mill materials. The materials are passed through a mesh or screen for desired size reduction. - What materials can the multi

mill machine handle?

It can process a wide range of materials, including powders, granules, chemicals, and food ingredients. - Is the machine easy to

maintain?

Yes, the multi mill machine is designed for easy maintenance with simple cleaning and servicing procedures to ensure long-term performance. - Can the multi mill machine

be used for wet materials?

Yes, the machine is designed to handle both dry and wet materials, making it versatile for a variety of applications. - What industries use the

multi mill machine?

It is widely used in the pharmaceutical, food processing, chemical, and cosmetic industries for milling and mixing products. - What are the key benefits of

using a multi mill machine?

The machine offers uniform size reduction, high efficiency, versatility, and minimal wear and tear. It ensures high capacity and reduced downtime. - How does the machine ensure

uniform particle size?

The multi mill has an adjustable screen size that controls the particle size by regulating the material flow and the rotor speed. - What are the safety features

of the multi mill machine?

It is equipped with safety features such as overload protection, emergency stop buttons, and vibration monitoring for enhanced user safety. - How much capacity does an

industrial multi mill machine have?

The capacity can vary depending on the model, but it can handle large-scale production volumes, typically ranging from 50 kg/hr to several hundred kg/hr, depending on the application.

Benefits of Industrial Multi Mill Machine

- Versatile Usage Handles a wide range of materials, including powders, granules, and wet substances.

- Uniform Particle Size Produces finely milled

and uniform-sized particles.

- High Efficiency Fast milling, resulting

in greater production capacity and reduced processing time.

- Easy to Clean and Maintain Designed for quick

disassembly and cleaning, ensuring a hygienic operation.

- Durable and Long-Lasting Built with high-quality

materials to ensure the machine has a long service life.

- Flexible for Different

Industries

Ideal for use in pharmaceutical, food, chemical, and cosmetic

industries.

- Improved Mixing Ensures even distribution

of materials, enhancing the final products consistency and quality.

- Compact and Space-Saving Ideal for industries

where space efficiency is important.

- Energy Efficient Consumes less power while

delivering high performance.

- Safety Features Equipped with features

that ensure safe operation, protecting both the machine and operators.

Uses of the Industrial Multi Mill Machine

- Pharmaceutical Industry Granulating and blending

of tablets and powders.

- Food Processing Milling spices, grains,

and other food materials into fine particles.

- Chemical Industry Grinding and mixing of chemicals and additives for the production of different formulations.

- Cosmetics Homogenizing and blending

various cosmetic ingredients for creams, lotions, and powders.

Applications of the Industrial Multi Mill Machine

- Granulation and Size

Reduction

For creating fine granules or powders in pharmaceutical production.

- Powder Mixing For blending powders in

food processing and chemical manufacturing.

- Particle Coating For uniform coating of

particles in pharmaceuticals and food products.

- Emulsifying Used for the creation of

emulsions in cosmetic and pharmaceutical industries.

- Shredding Ideal for shredding materials such as plastic, fibers, and other solid substances in various industries.

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Supplier in Gujarat

- HighβEfficiency Fluid Bed Dryer Gujarat

- High-Efficiency Fluid Bed Dryer Gujarat

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator β Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine