Electric Roll Compactor Machine Manufacturer in India

Electric Roll Compactor Machine Manufacturer in

India

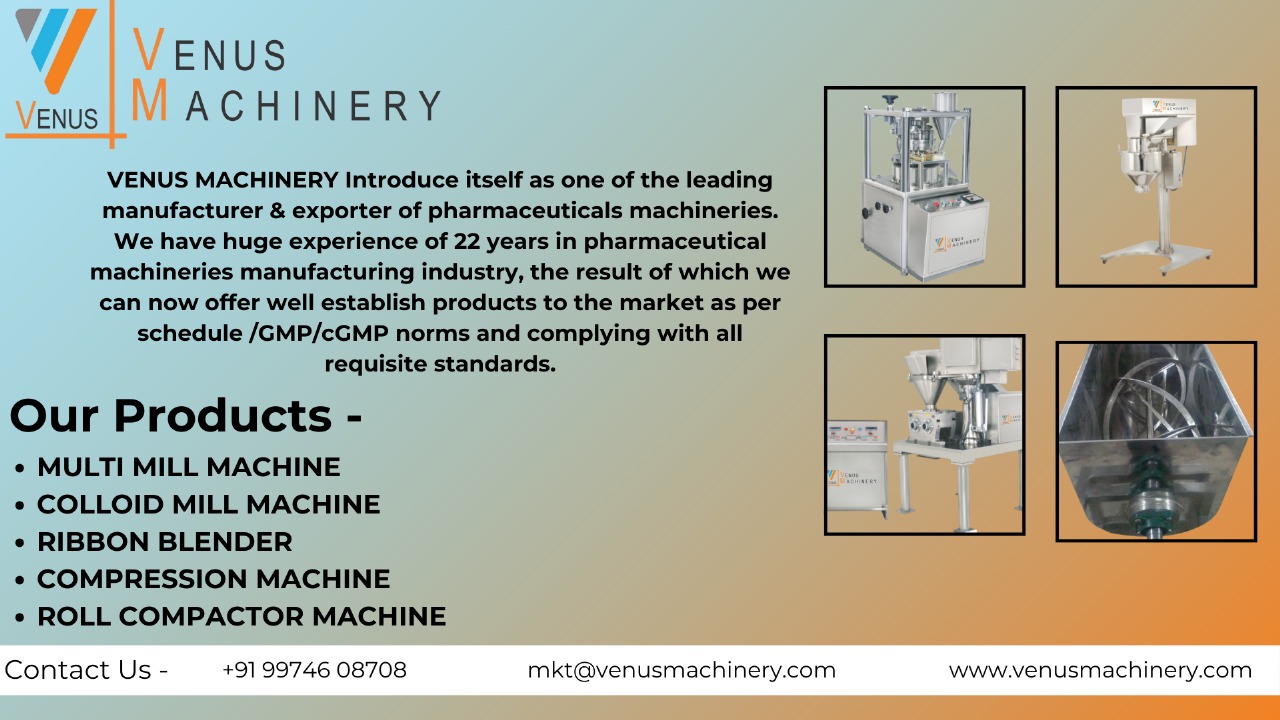

An ElectricRoll Compactor Machine is an innovative equipment widely used in the pharmaceutical,

chemical, and food industries to compact powder or granular

substances into a dense, uniform mass or sheet. As a leading manufacturer of

electric roll compactors in India, we provide highly efficient and robust

machines designed to maximize output while maintaining high levels of consistency

and quality in the compaction process.

FAQs: Electric Roll Compactor Machine in India

- What is an electric roll

compactor machine?

It is a machine that compacts powder or granular materials into dense, solid sheets or cakes by applying controlled pressure using rotating rolls. - What industries use electric

roll compactors?

Electric roll compactors are commonly used in industries like pharmaceuticals, chemicals, food, plastics, and fertilizers. - How does an electric roll

compactor work?

The machine utilizes electric motors to rotate two rolls at adjustable speeds, which compress the material between them, creating uniform sheets or cakes. - Is the electric roll

compactor easy to operate?

Yes, the machine comes with user-friendly interfaces and automated controls for easy operation, minimizing the need for manual intervention. - What are the advantages of

using an electric roll compactor?

They provide precise compaction, uniformity in material, and are ideal for large-scale production with consistent quality. - Is the electric roll

compactor energy efficient?

Yes, electric roll compactors are designed to be energy efficient, reducing power consumption while maintaining high output. - Can the compactor be

customized for specific needs?

Yes, electric roll compactors can be tailored to meet the specific volume, pressure, and compaction requirements of different industries. - How do I maintain an

electric roll compactor?

Regular maintenance includes cleaning, lubrication, and periodic checks of the rolls, electric motors, and control systems. - Can electric roll compactors

be used for both dry and wet materials?

Yes, the machines can be used for both dry and wet materials, depending on the compaction needs and settings. - What safety features are

included in the electric roll compactor?

Electric roll compactors are equipped with safety interlocks, emergency stop buttons, and guardrails to ensure safe operation.

Applications of Electric Roll Compactor Machine

- Pharmaceuticals: Compacting powders into

granules for tablet manufacturing.

- Chemical Industry: Used for compacting

chemical powders and granules.

- Food Processing: Granulation of food

ingredients like sugar, salt, and spices.

- Plastics Industry: Compaction of plastic

powders or pellets for molding.

- Fertilizers: Granulation of fertilizers

for easier handling and storage.

- Cosmetics: Compacting raw materials like talc and powder-based ingredients.

- Detergents and Soap: Granulating raw materials

for detergent production.

- Agriculture: Compaction of pesticides,

herbicides, and fertilizers.

- Mining and Minerals: Granulation of mineral ores

and powder materials.

- Waste Management: Compacting waste materials

for reduced storage volume.

Key Benefits of Electric Roll Compactor Machine

- Enhanced product uniformity

and consistency

- Higher compaction efficiency and throughput

- Energy-efficient operation, reducing costs

- Reduced material wastage due to accurate compaction

- Automated and

easy-to-operate controls

- Customizable settings for varying product

requirements

- Minimal maintenance due to robust design

- Compact design, ideal for limited floor space

- Versatile applications across multiple industries

- Improved product shelf life due to compact storage

Common Uses of Electric Roll Compactor Machines

- Tablet Manufacturing: Creating uniform granules

for tablet pressing in pharmaceuticals.

- Granulation of Chemical

Powders:

Used in the production of fertilizers, pesticides, and detergents.

- Food Ingredient Compaction: For materials like sugar,

cocoa, and milk powder in the food industry.

- Cosmetic Compaction: For talc powder, face

powder, and other cosmetic ingredients.

- Plastic Pelletizing: Compaction of plastic

materials to form uniform pellets for molding.

- Mineral and Ore Compaction: For granulating minerals

for easier handling and processing.

- Agricultural Product

Granulation: For

fertilizers and soil conditioners.

- Plastic Reprocessing: To compact and prepare

recycled plastic materials for molding.

- Waste Reduction: Used in waste management to reduce volume and improve storage efficiency.

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Supplier in Gujarat

- High‑Efficiency Fluid Bed Dryer Gujarat

- High-Efficiency Fluid Bed Dryer Gujarat

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) � Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender � Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine