Small Roll Compactor Machine Manufacturer in India

Small Roll Compactor Machine Manufacturer in India

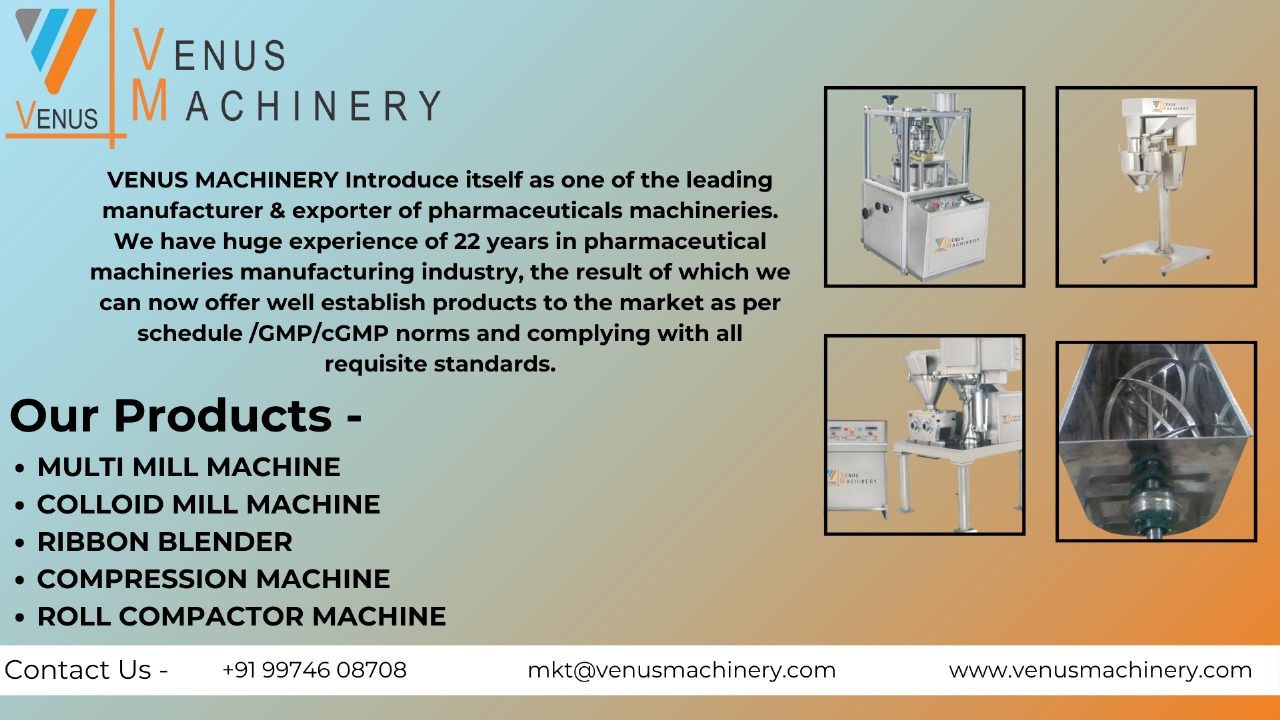

India’s

top small roll compactor machine manufacturers specialize in designing

space-saving, high-performance equipment for dry granulation needs in the

pharmaceutical, chemical, and food processing industries. These machines

compress fine powders into granules without moisture, making them ideal for

heat- and moisture-sensitive products. With precise control and low operational

cost, small roll compactors are a must-have for any lab-scale or medium-scale

production unit.

FAQs:

- What is a small roll

compactor machine used for?

It is used for dry granulation – compressing powders into uniform granules without using a liquid binder. - What industries use roll

compactors?

Commonly used in pharmaceuticals, nutraceuticals, chemicals, agrochemicals, and food processing. - What is the difference

between a roll compactor and a granulator?

Roll compactors are used for dry granulation, whereas granulators may require wet binders or solvents. - Is it suitable for R&D

or small-batch production?

Yes, small roll compactors are ideal for pilot batches, lab testing, and small-scale production. - What is the output capacity

of a small roll compactor?

Typically ranges from 1 kg/hr to 100 kg/hr depending on the model. - What kind of maintenance

does it require?

Regular cleaning, lubrication, and roll inspection are essential; overall low maintenance. - Does it come with a

granulation system?

Yes, most models include an integrated granulator and flake crusher. - Can I process heat-sensitive

products?

Absolutely – dry granulation avoids heat or moisture, preserving material properties. - How much space does a

compact roll compactor need?

They are designed for space efficiency and can fit into standard lab or small factory setups. - What is the price range in

India?

Prices start around ?3.5 lakhs and go up based on customization, automation, and output capacity.

Applications:

- Pharmaceuticals – Tablet and capsule

granulation

- Nutraceuticals – Herbal and protein

supplements

- Agrochemicals – Pesticides, fertilizers

- Chemicals – Dry powders and bulk

materials

- Food & Spices – Seasonings and dry mixes

Key Features:

- Compact, portable, and

ergonomic design

- Stainless steel (SS 304/316)

contact parts

- Variable roll pressure and speed control

- Integrated granulator and

flake crusher

- Easy disassembly for

cleaning

- Touchscreen HMI and

PLC-based operation (optional)

- Low noise, low vibration

- Dust-free and GMP-compliant

build

Uses:

- Converting fine powders into

granules

- Increasing bulk density for further processing

- Improving flowability and

uniformity

- Preparing materials for

tablet compression

- Reducing product loss during

production

Benefits:

- Ideal for small-scale or

pilot production

- Eliminates the need for

drying, reducing energy cost

- Enhances product consistency

and quality

- Quick changeover and easy

cleaning

- Reduced downtime and higher

productivity

- Cost-effective granulation

solution

- Ideal for heat- and moisture-sensitive products

- Safe and GMP-standard

compliant

- Long lifespan with minimal

maintenance

- Supports innovation and

formulation testing in R&D

Contact us more detail :

Call - +91 99746 08708

Email - mkt@venusmachinery.com

Address : 29, Sarovar Industrial Estate,

Hathijan Circle, S.P. Ring Road, Vatva, Ahmedabad - 382445, INDIA

Our Blogs

- Fluid Bed Dryer Exporter from Ahmedabad

- SS Fluid Bed Dryer Manufacturer

- Fluid Bed Dryer for Pharma Industry

- GMP Fluid Bed Dryer Manufacturer in Ahmedabad

- Heavy-Duty Compression Machine Supplier in Gujarat

- Compression Machine for Concrete Testing in India

- Automatic Compression Testing Machine (CTM)

- Digital Compression Testing Machine

- Best Compression Testing Machine Supplier in India

- Top Compression Machine Manufacturer in Gujarat

- Compression Machine Exporters from Ahmedabad

- Compression Testing Machine Manufacturer in India

- Hydraulic Compression Machine Manufacturer in Ahmedabad

- Deburring and Dedusting Machine Manufacturer in India

- Lab Testing Compression Machine Ahmedabad

- Fluid Bed Dryer for Powder Drying in India

- Leading Compression Machine Manufacturer in Ahmedabad

- Top Fluid Bed Dryer Manufacturer in India

- Leading GMP Oscillating Granulator Machine Manufacturer

- Pharmaceutical Fluid Bed Dryer Manufacturer

- Stainless Steel Oscillating Granulator – Ahmedabad

- Fluidized Bed Dryer Supplier Gujarat

- Industrial Fluid Bed Dryer in Ahmedabad

- Oscillating Granulator for Pharma Industry

- Fluid Bed Processor Supplier in India

- SS Oscillating Granulator Exporter from Ahmedabad

- Fluid Bed Dryer Manufacturer in Ahmedabad

- Dust Extractor Machine Supplier

- Roll Compactor Manufacturers

- Ribbon Blender Manufacturer in Ahmedabad

- Electric Roll Compactor Machine Manufacturer in India

- Roller Compactor Machine for Pharmaceutical Industry

- Vibro Sifter Manufacturer in Mumbai

- Vibro Sifter Manufacturer in Ahmedabad

- Sintex Water Tank Manufacturer

- Vectus Water Tank Price 1000 Ltr

- 500 Litre Liquid Storage Tank Manufacturer

- Vibro Sifter Machine Manufacturer in India

- Liquid Storage Tank Manufacturer near Naroda, Ahmedabad

- Oscillating Granulator Machine Manufacturer

- Liquid Storage Tank Manufacturer near Ahmedabad, Gujarat

- Industrial Vibro Sifter Machine Manufacturer

- Horizontal Drive Manufacturer

- Vibro Sifter Working Principle

- Vibro Sifter Manufacturer in India

- Industrial Multi Mill Machine

- Multi Mill Machine Manufacturers

- Dust Extractor Machine Manufacturers

- Mass Mixer Machine Manufacturers

- Rapid Mixer Granulator (RMG) Sensors

- Double Cone Blender Manufacturers in India

- Colloid Mill Machine Manufacturers in Maharashtra

- Rapid Mixer Granulator (RMG) – Capacity Guide

- Colloid Mill Machine Manufacturers in India

- Rapid Mixer Granulator principal (RMG)

- Roll Compactor Machine Manufacturer in Ahmedabad

- Rapid Mixer Granulator (RMG)

- Industrial Roll Compactor Machine Manufacturer Solutions

- Roll Compactor Manufacturers in India

- Double Cone Blender Construction

- Small Roll Compactor Machine Manufacturer in India

- Roll Compactor Manufacturers in India

- Double Cone Blender – Pharmaceutical

- Double Cone Blender Manufacturer Near Me

- Ribbon Blender

- Cone Blender

- Octagonal Blender

- Camphor Machine

- Compression Machine

- Deburring and Dedusting Machine

- Tablet Machine

- Roll Compactor Machine